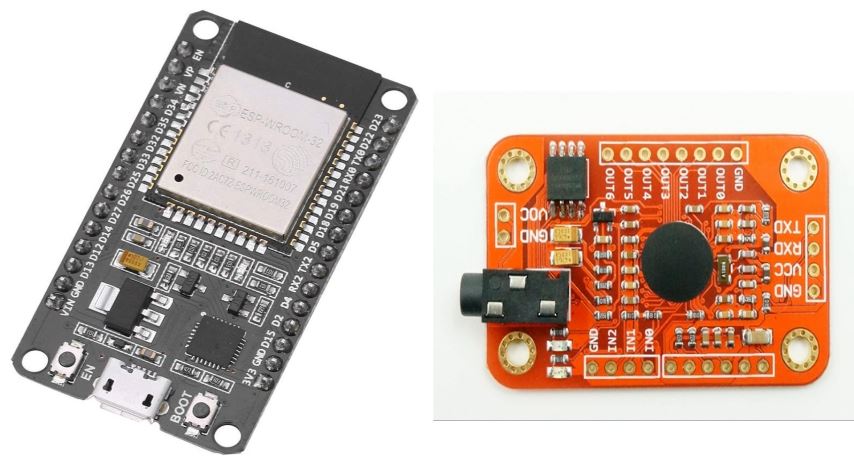

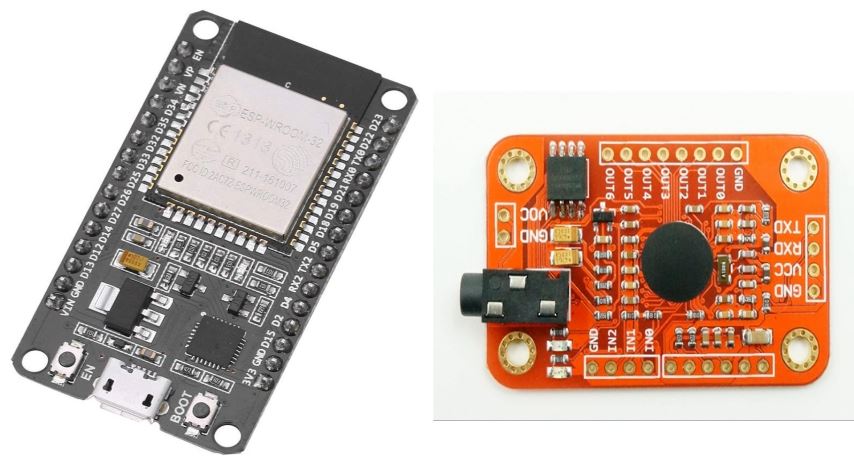

As part of a recent project to add standalone voice control to an oscilloscope, I wanted to marry an Elechouse voice recognition module V3 to an ESP32. Which worked out quite well, hence I’m making both the hardware information and…

As part of a recent project to add standalone voice control to an oscilloscope, I wanted to marry an Elechouse voice recognition module V3 to an ESP32. Which worked out quite well, hence I’m making both the hardware information and…

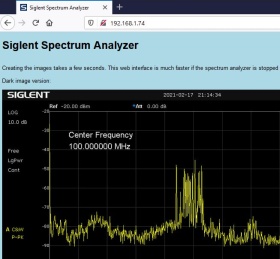

I have a Siglent SSA3021X spectrum analyzer. I like it a lot, and it’s been used for some other posts here. For example looking at LORA signals. I’ve long wished it had a web interface for screen captures. So I…

I’ve been doing an interesting project, writing some LoRa code in Python on an ESP32. There are lots of resources on the web, including other example codebases in github etc, which means I didn’t have to start from scratch. Fairly…

We have a couple of bathrooms each containing five 100W halogen 78mm R7S light bulbs. Those things get hot; it’s like having a heater in there, even in the summer! Plus burning 500 watts is a great way to jack…

We have a 2013 Hyundai Elantra GT hatchback. It’s a little over 5 years old and the back hatch no longer stays up. The lift supports struts had worn out. Five years is a pretty short life for lift supports…

This is a test of the DIOT MQTT plugin. Although it looks rather boring, I’ll leave this post up because it’s useful for testing. Some data should appear. If you see any numbers changing, then the plugin is working.

MQTT is a simple protocol for sharing small packets of data with multiple devices. Although it’s been around since 1999, the last few years it’s been growing in popularity as part of the whole “internet of things” movement. I decided…